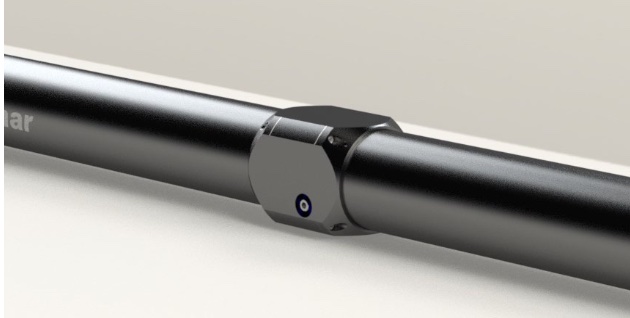

Bamar E – vang

Bamar has developed a Patent pending, ground breaking eco-friendly electric boom vang, to replace hydraulic vangs in all their functions.

This innovation involves several advantages:

- Eco friendly: no oil on board, but a very high energy saving equipment (the current size available, with a 600W nominal power motor reaches a maximum intermittent pull of over 11000kg, suitable for 50’ -65’ sailing yachts);

- Easy installation: no hoses and manual or hydraulic control units, simply connect to the 12/24/48V on-board power supply;

- Easy use: controlled by 3 switches (Up – Down – Emergency Quick Release high speed);

- Connectivity: connect the electric vang to the on-board automation monitoring and management system (limit switch sensors, load cell, ampere absorption, possible position sensor);

- Active safety: the dynamometric pin recognizes the external compression loads exerted by the boom/mainsheet and allows the vang to automatically adapt following the sail adjustment requirements (preventing wrong manoeuvres or overloads);

- Passive safety: in the event of an electrical blackout on-board, thanks to a manual emergency backup clutch, the unit can be extended or retracted with a standard winch handle or a power drill.

Bamar E-Vang, is driven by a state-of-the-art electric motor. Through a planetary reduction gear, the motor transmits the motion to a screw which develops the pulling loads required.

E-Vang is supplied with an electronic box. Its software manages the cylinder operation and the information supplied by the sensors installed on the unit itself, thus allowing all manoeuvres to be carried out safely.

The dynamometric pin transmits the compression load to the electronic box, so as to adjust the vang extension depending on external stresses (e.g., the boom lowers because the mainsheet is being pulled. The vang automatically adapts its length by retracting);

The unit is provided with 2 stroke-end sensors which intervene to block manoeuvres (In-Out), thus preventing errors, and guaranteeing safety on board.

In case of need, to unload the mainsail leech while sailing and avoid broaching, the user may activate the vang release at maximum speed via the “Emergency Quick Release high speed” control switch (10 mm/s compared to 5.5 mm/s standard use speed).

Manual emergency use: the boom vang is supplied with a manual emergency clutch. In the event of an

electrical blackout, you may either extend or

retract the unit by means of a standard winch handle or a battery powered drill.

Electric boom vangs can be made in multiple sizes with different dynamic pull to cover all needs.

The units are manufactured with CNC machines from certified solid bars of material. Bodies are made in anodized aluminium alloy and studs/pins are made in special steel.

Electric motors are combined with planetary gearboxes for maximum efficiency with minimum electric absorption. They can be either equipped with permanent magnets for the standard DC versions, or brushless for the custom versions (400V AC)

The standard dynamometric pin is equipped with a watertight plug and multi-polar cable to be wired onto the electrical/electronic box. Otherwise, the custom version can be supplied with a wireless dynamometric pin.

Take a look at our range of Bamar furlers today or get in touch with us to discuss your requirements.

Please scan to download instruction manual